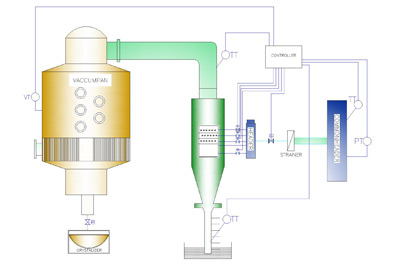

Condenser Automation

Condenser Automation

Condenser Automation:

- Multiple Entry Condenser Box.

- Separate Water Entry for Different Sets of Spray Nozzles and Spray Jet and Water Quantity is Automatically Controlled to by ON/OFF Valve for Respective Nozzle Set Valve wrt Vacuum.

- Number of Jets & Nozzles and Jet & Nozzle Diameters designed as per Condenser Capacity.

- Complete Stainless Steel Construction, Strainer provided for each Condenser Header.

- Water Pressure in the Common Injection Header maintained by Controlling Injection Pump VFD.

- Jet Compartment Controlled by Separate Valve.

- Vapour and Tail Pipe Temperature Measured.

Principle:

- As Massecuite Level in Pan rises, Rate of Evaporation Reduces and therefore Water Quantity required to create Vacuum also reduces. Thus any Extra Water used after this point is a Wastage.

- Condenser Automation facilitates Required Vacuum Generation using just Optimum Water and Power, thus reducing Wastage of Excess Energy and Water.

- Temperature difference between Vapour and Vapour-Condensate also affects Vacuum Generation and so does the Injection Water Temperature which varies as per Ambient.

Purpose:

- Huge Power and Water Saving due to Controlled intake of Water.

- Facilitate Optimum Capacity Utilization.