Sugar Process Automation Consists Of Following Systems:

- Juice Heater Control System

- pH and lime Dozing Automation

- Clarifier Automation

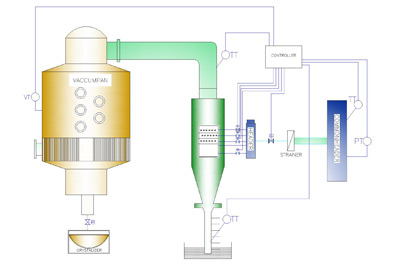

- Evaporator Automation

- Batch and Continuous Pans Automation

- Continuous Centrifugal Machine Automation

- Vertical Crystallizer Automation

- Sugar Melter Automation

- Molasses Conditioner Automation

- Superheated Wash Water System

- Pressure reducing and Desuperheating Station Automation

- Steam and Vapor Balancing System

- Condenser Automation

Operational advantages of Process Automation:

- Stabilized Shock Lime and Final pH ensures Improvement in Juice Clarity, Stabilized Dorr pH.

- Constant Evaporator outlet Brix Ensures smooths further Sugar Manufacturing Process.

- Evaporator Level is maintained hence Entrainment through Vapor is eliminated.

- Constant Evaporation results in Constant Vapor Generation hence better Heat efficiency.

- Pan Automations ensure Maintained Grain Size thus better and constant Sugar Quality.

- All the above advantages ensure Better Sugar Color thus Higher Sugar Price.

- Increased Throughput in the same operation time and Optimum Capacity Utilization.

- Saves Power, Steam and water thus Fuel Saving.

- Reduced Cost of Operation effect Substantial Economic Gains.