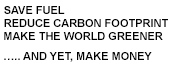

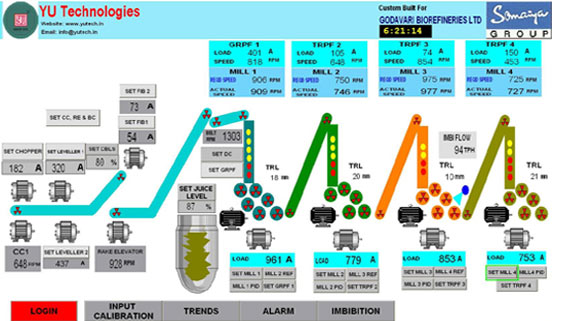

YUTECH Automation in Sugar Mill Operation ensures the following advantages.

- Increased Milling with the same equipment.

- Continuous and Uninterrupted Feeding reduces Downtime and Increase Throughput.

- Elimination of Choking at Preparatory Devices, Mills, Chutes or Carriers.

- Maintained Juice to Imbibition Water Ratio increases Evaporation Efficiency.

- Optimum Mill Speeds with respect to Loads and Levels ensure good Milling Results at all times.

- Effective water saving and cutting off water flow when crushing is stopped.

- Constant juice Flow for process ensures even loading in the Boiling House and Stabilizes and Reduces the steam Consumption which means higher Boiling House efficiency and Bagasse Saving.

Features:

- Infra Red Type Donnelly Chute Sensors(We invented & are the only manufacturer of IR Sensors for Donnelly Chute Level)

- Radiometric top Roller Lift sensors.

- Precision Motor load/ pressure Sensors.

- Customized software is user friendly and the field data inputs ensure constant loads on the Mills at all times.

Block Diagram Of Mill Automation System

YUTECH Mill Automation Maximizes Performance & Saves:

- Power

- Steam

- Fuel

- Costs

Thereby Generates Sustained Revenues Year on Year